HyperMES®

The MES/MOM for production advancement, optimization and monitoring

HyperMES is the Real Comm MES/MOM solution that enables comprehensive and efficient management of production events and progress tracking.

A Manufacturing Execution System (MES) is software designed primarily to manage and control the production area within a company, while Manufacturing Operations Management (MOM) represents the evolution of MES with additional functionalities.

Customizable

Multilingual software fully adaptable to the specific production needs of your company.

Integrable

Supports direct connection to machinery, acquiring essential information for effective production control.

What HyperMES Offers:

Integration with scheduling tools or corporate ERP systems

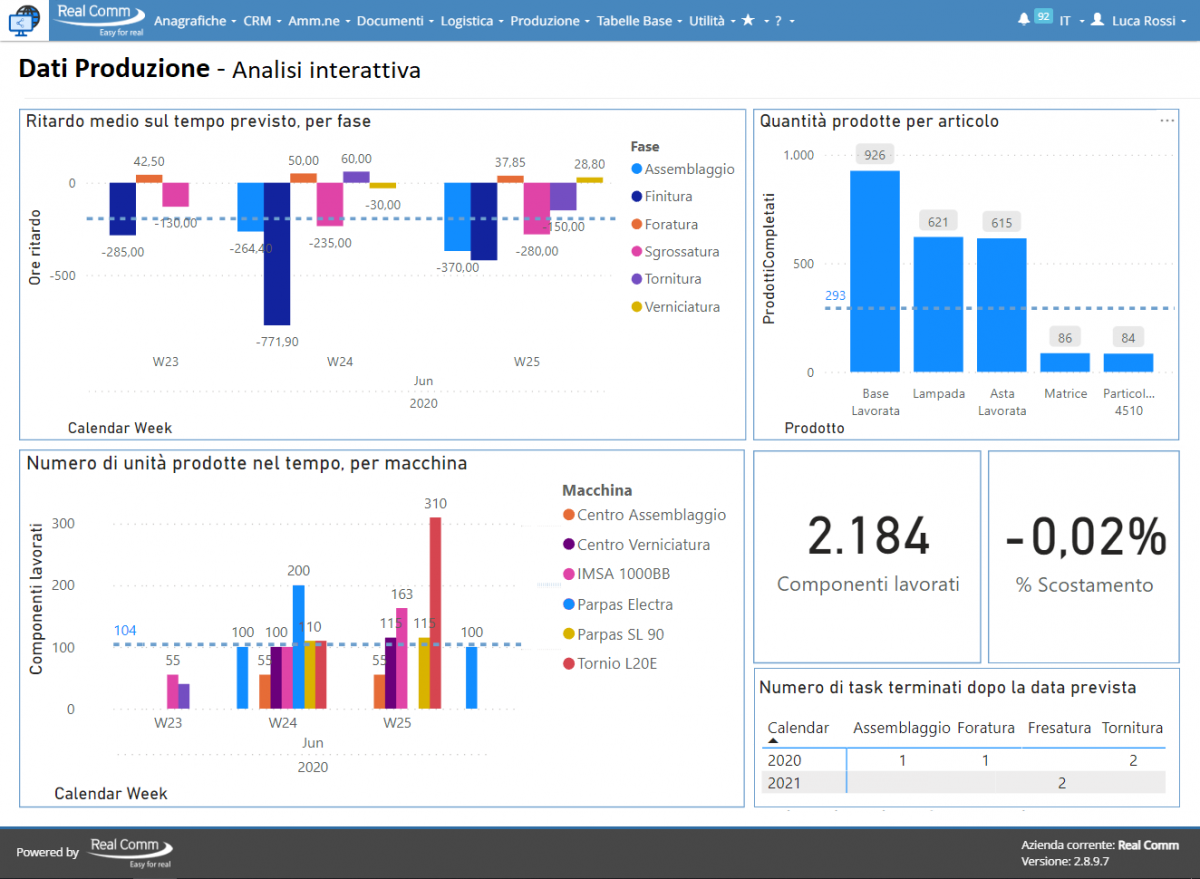

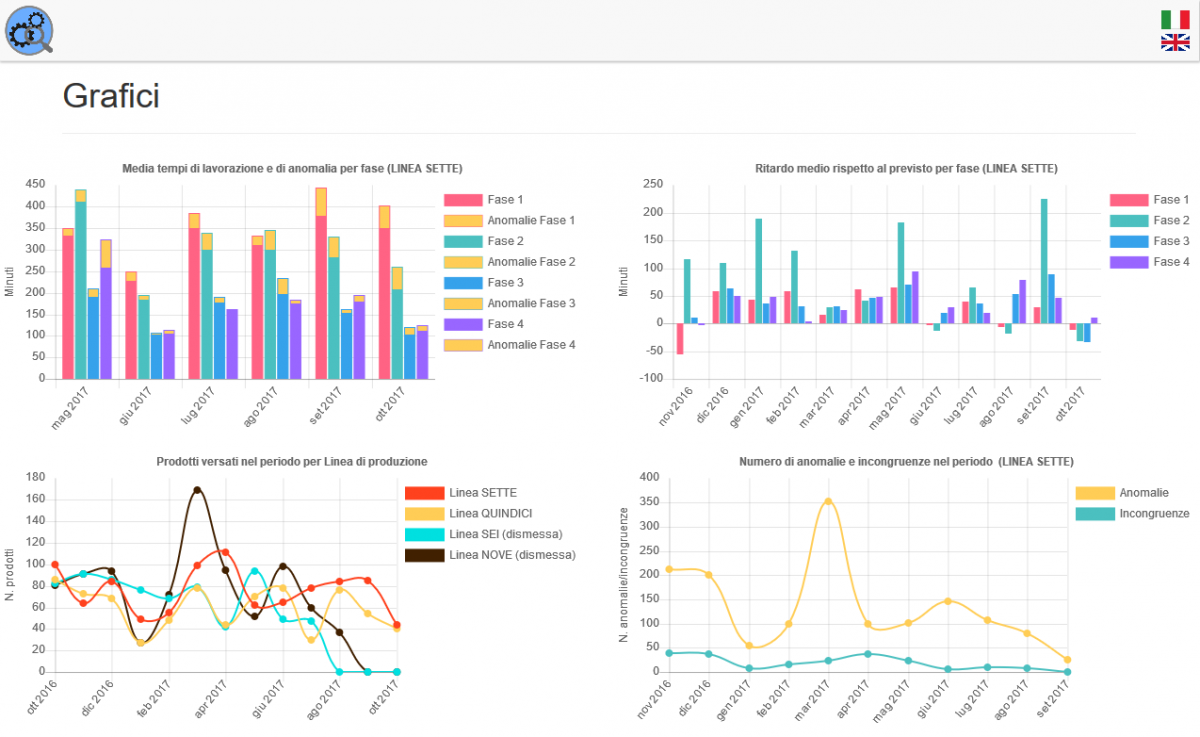

Production data analysis: times, costs, margins, and variances

Real-time communication of information to operators

Traceability, Quality Plans, Maintenance Plans

Intuitive dashboards for real-time production monitoring

Integration with Microsoft PowerBI

Key Features:

Traceability

Full monitoring of produced units, ensuring transparent and reliable management.

Quality Plans

Natively integrated with HyperQLT, the module designed for quality plan management, ensuring seamless integration between quality control and production management.

Maintenance Plans

Integrated with maintenance plans, allowing visualization of not only production tasks but also maintenance activities associated with machinery.

WMS

Integrated with the WMS module, providing support for logistics processes, seamlessly connected with production, purchasing, and sales areas.

Additional Capabilities of HyperMES:

- Production Progress Management: Tracks the progress of activities for machines, operators, departments, and lines, offering a precise and real-time view of production status.

- Recording Withdrawals and Deposits: Accurately registers the movement of produced units within inventory, managing both withdrawals and deposits to ensure complete traceability throughout the production cycle.

Benefits:

- Increased Production Efficiency

- Efficient Integration of ERP and Machinery

- Management of Downtime and Anomalies