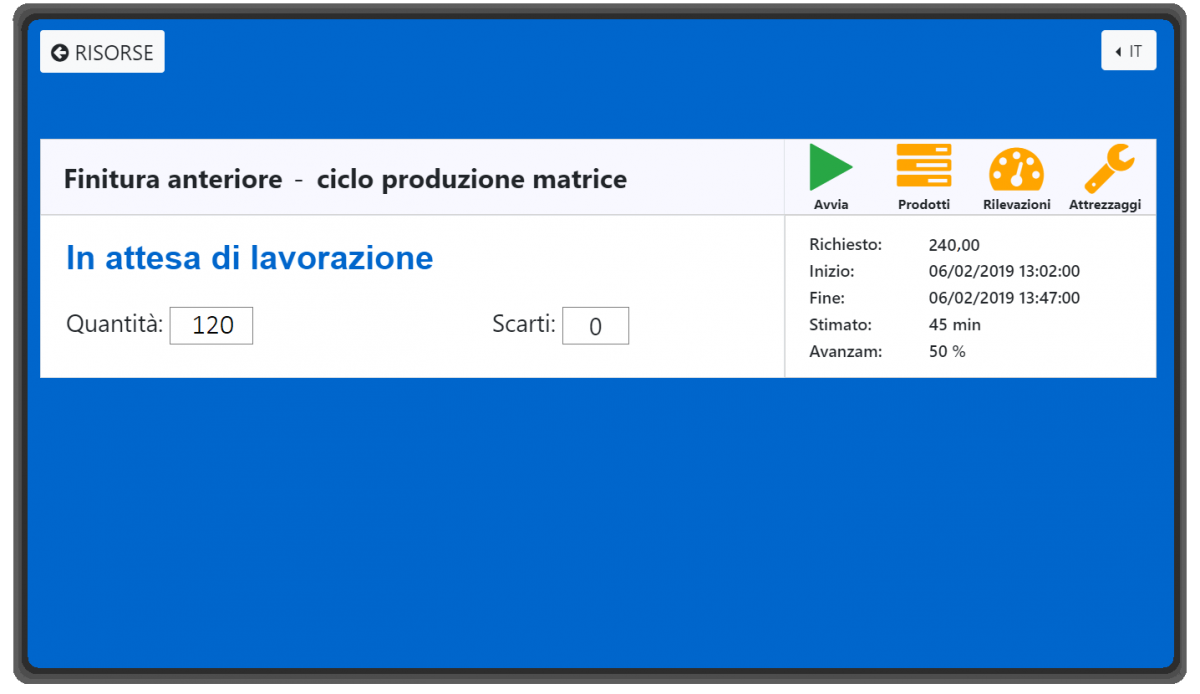

Application for detecting progress in work centers

HyperTAB simplifies and speeds up the declaration of activities by operators, with a view to Industry 4.0 . The software features a simple interface and is accessible on tablet, industrial tablet, or PC.

Directly integrated with HyperSCHED® and HyperMES® allows bidirectional transmission of information : enabling bidirectional information transmission: it allows operators to know the list and technical details of scheduled work, and production managers to obtain direct information on progress.

The exchanged information includes:

- Items / components to be produced

- expected / actual times

- compliant quantities / rejects

- part program

- notes

- technical drawings

- set-up timing

By linking it to HyperMES® it enables the detection of production-related events:

- machine stops

- rework

- meetings

- others freely definable

Allows operator recognition through various methods: codes, barcode readers, or NFC-based wearable devices.

For Industry 4.0 , HyperTAB automatically acquires information on times and quantities produced ; a panel with sensor-detected data will also be displayed, with configurable alarm thresholds, with configurable alarm thresholds, for continuous and real-time monitoring of process data.

The national Industry 4.0 plan encourages the modernization of your company with Hyper Depreciation up to 270% which allows a minimum fiscal saving oh 40% of the invested capital.

HyperTAB

HyperTAB